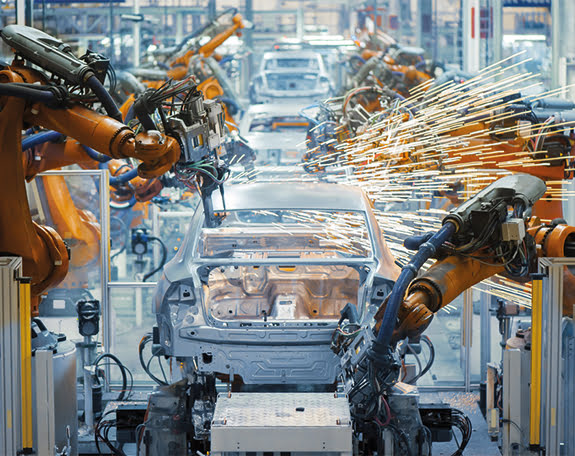

Automotive Industry

Polymers

It is used in interior cladding, seats, bumpers, under the hood, upholstery, front console, electrical systems, fuel systems, chassis, lighting systems, exterior parts, liquid tanks, and other parts in the automotive industry.

Engineering

Plastics are constantly being adapted to meet the needs of the electronic cars of the future.

Automotive

Polymers in their applications contribute significantly to the desire to build better, safer, and cleaner cars.

Medical Industry

Audit

With a variety of distinctive polymers to fulfill the requirements of the often audited medical industry, reliable products for the pharmaceutical and medical industries are provided.

Development

Material selection, mold design recommendations, Mold Flow analysis, chemical resistance information, sterilization suitability recommendations, production conditions recommendations, and certificates required by legislation are all provided throughout the entire process, from the product development phase to the finished product.

Sector-Specific Service

Relevant technical service and application development teams, specific to the sector, serve to meet the demands of customers.

White Appliances Products

Hygiene

White appliances use plastic cabinets, containers, boxes, and shelves that are all created in one piece and conformity with hygienic standards. As a result, stronger, lighter, and thinner plastic parts become available.

Performance

Thanks to polymers, high performance and comfort features are offered.

Diversity

As polymer engineering advances, products are being designed more and more following customer specifications. The white appliances business now has more diversity as a result of this.

Construction Industry

Durability

Polymers offered for the construction industry; It is widely used in the building and construction industry due to its many features such as having a light and yet strong structure, durability, good toughness, affordable cost and maintenance costs, and high insulation properties.

Implementations

Polymers in the building and construction industry, floor coverings, roof components, sealing, insulation, window frame, door, varnish, column cornice, lamination and decoration flooring, balustrade, waste water drain, armature, pipe, gutter and drainage systems, wallpapers, paint It can be used in different applications such as adhesive, flooring, fiber (fabric and carpet), anti-vibration seismic isolator, earthquake strengthening and improvement of structure, plastic timber, earthquake reinforcement in bridges and foundations.

Packaging Industry

Innovative Approach

Applications for smart polymers that are new and inventive are developing in response to consumer expectations for products that are healthy, comfortable, and environmentally friendly. In polymers given to the packaging sector, compliance with food contact, effectiveness, and functionality are taken into account.

Product Range

The wide range of applications in the polymer world enables it easier to reach products with the desired qualities.

Features

It is ensured that the structural characteristics of polymeric packaging are compatible with the product to be used as packaging and are suitable for environmental conditions in areas of storage and transport.

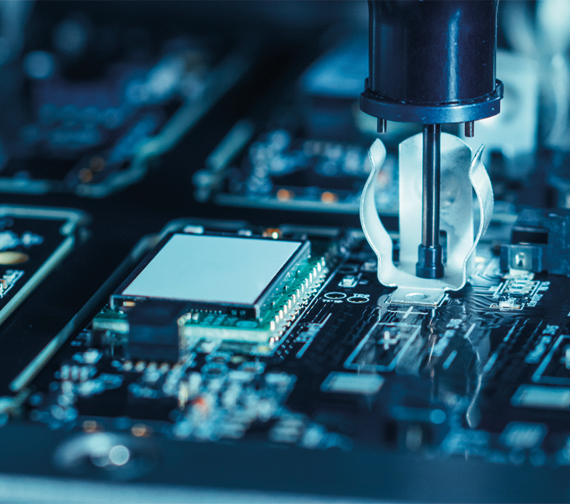

Electronics Industry

Innovative Approach

Many of the most recent gadgets developed in the electrical and electronics industries, from basic connections and home appliances to smartphones, use next-generation plastics, namely polymers. Thanks to their diversity and adaptability, polymers significantly contribute to innovation in the electrical and electronics sector.

Productivity

Because of its special characteristics, the polymer is chosen by designers of electrical and electronic applications. These characteristics include resistance to fire, lightweight, and resource efficiency.

Energy Saving

Polymers provide flexibility, durability, and the capacity to allow energy to be stored for longer periods. They can also have flame-retardant qualities.